Understanding the Role of a Gasoline Dispenser Factory in Modern Fuel Stations

Understanding the Role of a Gasoline Dispenser Factory in Modern Fuel Stations

Table of Contents

1. Introduction to Gasoline Dispenser Factories

2. Historical Evolution of Gasoline Dispensers

3. Key Components of Modern Gasoline Dispensers

4. The Manufacturing Process of Gasoline Dispensers

5. Safety Standards and Regulations in the Industry

6. Technological Advancements i

Understanding the Role of a Gasoline Dispenser Factory in Modern Fuel Stations

Table of Contents

- 1. Introduction to Gasoline Dispenser Factories

- 2. Historical Evolution of Gasoline Dispensers

- 3. Key Components of Modern Gasoline Dispensers

- 4. The Manufacturing Process of Gasoline Dispensers

- 5. Safety Standards and Regulations in the Industry

- 6. Technological Advancements in Gasoline Dispenser Design

- 7. The Role of Gasoline Dispensers in Fuel Stations

- 8. Sustainability Initiatives in Gasoline Dispenser Manufacturing

- 9. Future Trends in Gasoline Dispenser Technology

- 10. Conclusion

- 11. Frequently Asked Questions

1. Introduction to Gasoline Dispenser Factories

The intricate machinery and sophisticated technology that fuel the modern world rely heavily on the efficiency of gasoline dispensers. As the backbone of fuel stations, **gasoline dispensers** not only facilitate the transfer of fuel but also serve as a crucial interface between the consumer and the fuel provider. Understanding the role of a **gasoline dispenser factory** is vital for grasping how these devices are manufactured, customized, and maintained to meet the ever-evolving demands of the market.

2. Historical Evolution of Gasoline Dispensers

The journey of gasoline dispensers began in the early 20th century with manual pumps that required considerable effort to operate. Over time, innovations such as electric pumps and digital displays transformed the landscape. With advancements in technology and consumer expectations, the design and functionality of gasoline dispensers have significantly evolved. Modern dispensers now feature touch screens, payment integrations, and even loyalty programs, highlighting the shift towards a more user-friendly experience.

3. Key Components of Modern Gasoline Dispensers

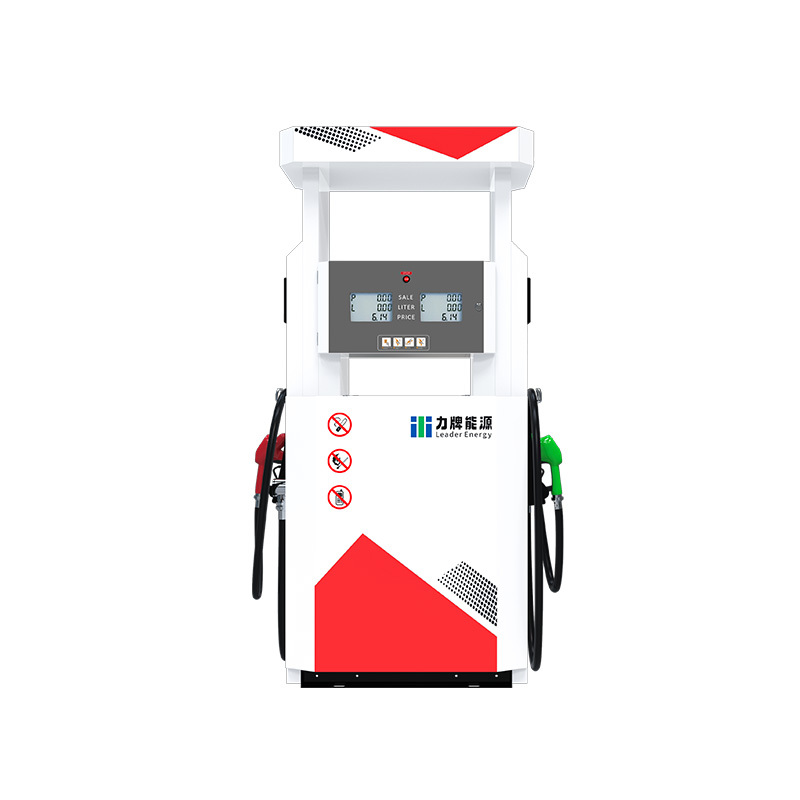

To fully appreciate the complexity of gasoline dispensers, one must understand the key components that allow them to function seamlessly. These components include:

3.1 Pumping Mechanism

The heart of any gasoline dispenser is its **pumping mechanism**, which is responsible for transferring fuel from storage tanks to the vehicle. High-efficiency pumps ensure that fuel delivery is quick and reliable, minimizing wait times for customers.

3.2 Metering System

The **metering system** accurately measures the volume of fuel dispensed, ensuring that customers are charged correctly. Advanced metering technology includes electronic calibration, which enhances accuracy and reduces the risk of discrepancies.

3.3 Payment Systems

Modern dispensers integrate sophisticated **payment systems** that support various payment methods, including credit cards, mobile payments, and RFID technology. This flexibility enhances customer convenience and satisfaction.

3.4 Safety Features

Safety is paramount in the design of gasoline dispensers. Features such as emergency shut-off valves, spill containment systems, and overfill protection mechanisms are critical in preventing accidents and ensuring safe operations.

4. The Manufacturing Process of Gasoline Dispensers

The manufacturing process of gasoline dispensers involves several meticulous steps, ensuring that each unit meets stringent quality and safety standards.

4.1 Design and Engineering

The initial phase involves extensive **design and engineering**, where concepts are developed into prototypes. Engineers use advanced software to create detailed models that incorporate safety features and technological innovations.

4.2 Material Selection

Choosing the right materials is crucial for durability and safety. Manufacturers often use corrosion-resistant materials such as stainless steel for the outer casing, ensuring longevity and resilience against harsh environmental conditions.

4.3 Assembly Line Production

Once the designs are finalized and materials selected, the assembly line production begins. Skilled workers and automated systems collaborate to ensure precision assembly of components, from the pumping mechanism to electronic systems.

4.4 Quality Control

Quality control is a vital step in the manufacturing process. Each unit undergoes rigorous testing for performance, safety, and compliance with industry standards before being shipped to distributors.

5. Safety Standards and Regulations in the Industry

Safety standards in the gasoline dispenser industry are critical for protecting both consumers and the environment. Various regulatory bodies, such as the **Occupational Safety and Health Administration (OSHA)** and the **Environmental Protection Agency (EPA)**, set guidelines that manufacturers and operators must follow.

5.1 Compliance with National Standards

Gasoline dispensers must comply with national standards such as those set by the **National Institute of Standards and Technology (NIST)**, which governs accuracy and measurement standards.

5.2 Environmental Regulations

With growing concerns about environmental impact, manufacturers are required to adhere to regulations aimed at minimizing spills and leaks. Many factories now implement closed-loop systems to prevent hazardous waste and protect groundwater.

6. Technological Advancements in Gasoline Dispenser Design

The evolution of technology has brought about significant improvements in gasoline dispenser design, enhancing both functionality and user experience.

6.1 Smart Dispenser Technology

Smart dispensers are equipped with IoT (Internet of Things) technology, allowing for remote monitoring and diagnostics. This innovation enables fuel station operators to track performance metrics and address issues proactively.

6.2 Enhanced User Interfaces

Modern dispensers feature user-friendly interfaces with touchscreens that provide clear instructions and options. These interfaces can display real-time fuel prices, promotions, and loyalty program information, creating a seamless customer experience.

6.3 Integration with Mobile Apps

Many fuel stations now offer mobile applications that integrate with gasoline dispensers. Customers can find nearby stations, view fuel prices, and even pay via their smartphones, streamlining the entire fueling process.

7. The Role of Gasoline Dispensers in Fuel Stations

Gasoline dispensers play a pivotal role in the operations of fuel stations, impacting everything from sales to customer satisfaction.

7.1 Customer Experience

A well-designed gasoline dispenser enhances the customer experience by providing quick, efficient service. Features like multiple payment options and loyalty rewards programs encourage repeat business.

7.2 Revenue Generation

Gasoline dispensers are a primary source of revenue for fuel stations. The volume of fuel dispensed and the pricing strategy directly influence profitability, making the reliability of these dispensers critical for operational success.

7.3 Operational Efficiency

Advanced technology in gasoline dispensers contributes to operational efficiency. Real-time data on fuel levels and dispenser performance enables station managers to optimize inventory and reduce downtime.

8. Sustainability Initiatives in Gasoline Dispenser Manufacturing

As sustainability becomes a central concern for industries worldwide, gasoline dispenser factories are increasingly adopting eco-friendly practices.

8.1 Energy-Efficient Manufacturing

Many manufacturers are implementing energy-efficient processes and using renewable energy sources in their production lines, reducing their carbon footprint and operational costs.

8.2 Recyclable Materials

The use of recyclable materials in the production of gasoline dispensers is becoming more common. Manufacturers are focusing on reducing waste and ensuring that materials are sourced sustainably.

8.3 Eco-Friendly Designs

Innovative designs that minimize environmental impact are gaining traction. Features such as automatic shut-off nozzles and spill containment systems help prevent fuel wastage and environmental contamination.

9. Future Trends in Gasoline Dispenser Technology

The future of gasoline dispensers is poised for remarkable transformation, driven by technological advancements and evolving consumer preferences.

9.1 Integration with Renewable Energy

As the world shifts towards renewable energy, future gasoline dispensers may incorporate technology to support alternative fuels such as biofuels and hydrogen, expanding their versatility.

9.2 Advanced Payment Solutions

The integration of cryptocurrency and blockchain technology into payment systems could revolutionize transactions at fuel stations, offering customers more secure and anonymous payment options.

9.3 Enhanced Data Analytics

Future gasoline dispensers may harness big data analytics to provide station owners with insights into customer behavior and purchasing patterns, allowing for targeted marketing and personalized services.

10. Conclusion

Gasoline dispensers are more than just machines; they are a vital component of the fuel supply chain that significantly contributes to the efficiency and effectiveness of fuel stations. Understanding the role of gasoline dispenser factories provides insight into the complex processes that drive innovation and ensure safety in the industry. As technology continues to advance, the future of gasoline dispensers will likely bring even more improvements, enhancing the experience for both consumers and fuel station operators.

11. Frequently Asked Questions

Q1: What are the key features of modern gasoline dispensers?

A1: Modern gasoline dispensers feature advanced metering systems, smart payment options, user-friendly interfaces, and safety mechanisms such as emergency shut-off valves.

Q2: How do gasoline dispenser factories ensure safety standards?

A2: Gasoline dispenser factories adhere to stringent safety regulations set by organizations like OSHA and EPA, conducting thorough testing and quality control throughout the manufacturing process.

Q3: What materials are used in manufacturing gasoline dispensers?

A3: Common materials include corrosion-resistant metals like stainless steel, which provide durability and longevity in various environmental conditions.