Understanding the Cutting-Edge Technology Behind High Flow Fuel Dispensers

Understanding the Cutting-Edge Technology Behind High Flow Fuel Dispensers

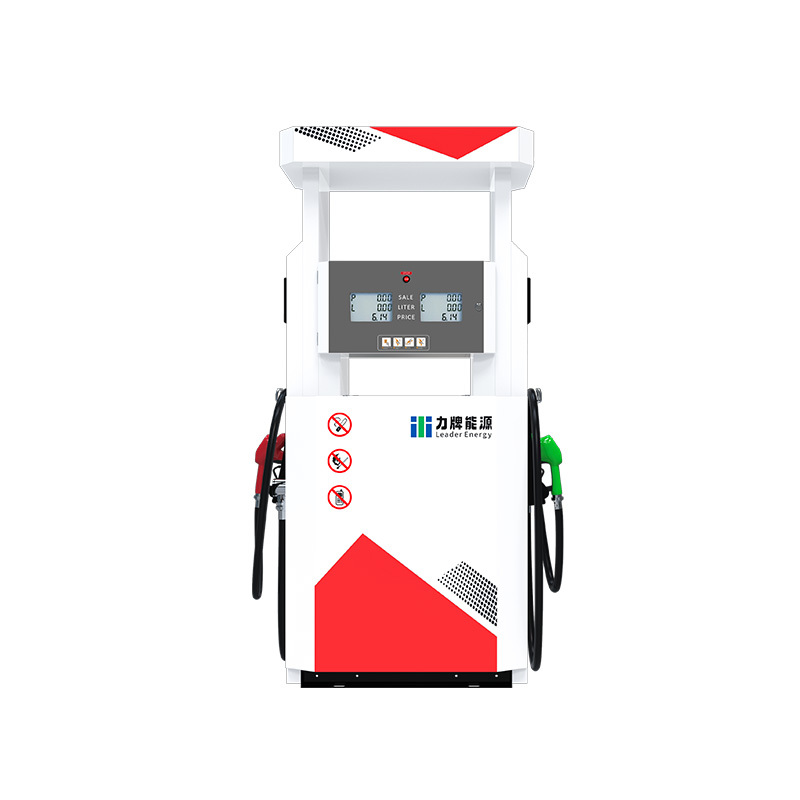

Fuel dispensing technology has seen remarkable advancements over the years. Among the most significant innovations are **high flow fuel dispensers**, which have become essential for operations requiring rapid refueling. This article explores the technology behind these cutting-edge dispensers, their components, benefits, an

Understanding the Cutting-Edge Technology Behind High Flow Fuel Dispensers

Fuel dispensing technology has seen remarkable advancements over the years. Among the most significant innovations are **high flow fuel dispensers**, which have become essential for operations requiring rapid refueling. This article explores the technology behind these cutting-edge dispensers, their components, benefits, and much more.

Table of Contents

- Introduction to High Flow Fuel Dispensers

- What Are High Flow Fuel Dispensers?

- The Technology Behind High Flow Fuel Dispensers

- Key Components of High Flow Fuel Dispensers

- Benefits of Using High Flow Fuel Dispensers

- Safety Features in High Flow Fuel Dispensers

- Maintenance and Reliability of High Flow Fuel Dispensers

- The Future of High Flow Fuel Dispensers

- FAQs

- Conclusion

Introduction to High Flow Fuel Dispensers

The increasing demands of the transportation industry have led to the development of high flow fuel dispensers. These dispensers are engineered to deliver fuel at a much faster rate than traditional dispensers, catering to the needs of various sectors, including commercial fleets, aviation, and large-scale industries. Understanding how these dispensers function is crucial for stakeholders in the fueling industry.

What Are High Flow Fuel Dispensers?

High flow fuel dispensers are specialized equipment designed to dispense liquid fuels at a higher flow rate, typically exceeding 40 gallons per minute (GPM). They are essential in scenarios where time efficiency is critical, such as refueling large vehicles or aircraft. By employing advanced pumping technologies, these dispensers ensure that fuel delivery is both swift and reliable.

Applications of High Flow Fuel Dispensers

High flow dispensers are predominantly used in commercial applications, including:

- Trucking fleets

- Aviation fuel stations

- Construction sites

- Marine fueling stations

Each application has specific requirements that high flow dispensers can meet, such as volume and speed of fuel delivery.

The Technology Behind High Flow Fuel Dispensers

The technology that powers high flow fuel dispensers incorporates various engineering principles. At the heart of these dispensers is a high-capacity pump, often paired with advanced metering systems to ensure accurate fuel measurement.

Pumping Mechanisms

High flow dispensers utilize different pumping mechanisms, including:

- **Positive Displacement Pumps**: These are designed to move a specific volume of liquid with each rotation, ensuring consistency in flow rates.

- **Centrifugal Pumps**: Common in many modern dispensers, these pumps are efficient for transferring liquids at high flow rates.

Metering Systems

Accurate measurement of dispensed fuel is paramount. High flow dispensers utilize:

- **Electromagnetic Flow Meters**: These meters provide precise measurement by detecting changes in magnetic fields as fuel flows through.

- **Mechanical Flow Meters**: Though less common in high flow applications, they rely on rotational movement to gauge the volume of fuel dispensed.

Key Components of High Flow Fuel Dispensers

Understanding the anatomy of high flow fuel dispensers allows users to appreciate their functionality better. Key components include:

1. High-Capacity Pump

The pump is the core of the dispenser, pushing fuel through the system at desired rates.

2. Flow Meter

The flow meter measures the amount of fuel dispensed, ensuring accuracy and compliance with regulatory standards.

3. Hose and Nozzle

These components facilitate the delivery of fuel to the vehicle. High flow hoses are designed to withstand the pressure of fast fuel delivery, while nozzles are ergonomically designed for ease of use.

4. Filtering System

To ensure the quality of the fuel dispensed, high flow dispensers are equipped with filtering systems that remove impurities and contaminants.

5. Control System

Modern dispensers often feature electronic control systems, allowing users to monitor and control deliveries with ease.

Benefits of Using High Flow Fuel Dispensers

The advantages of high flow fuel dispensers extend beyond mere speed. Their benefits include:

1. Improved Efficiency

By reducing refueling time, businesses can maximize operational hours and minimize downtime.

2. Enhanced Customer Satisfaction

In consumer-facing applications, speed of service can significantly improve customer satisfaction and loyalty.

3. Cost-Effective Operations

High flow dispensers reduce labor costs associated with refueling, especially in commercial settings where multiple vehicles may require simultaneous fueling.

4. Versatility

These dispensers can handle various types of fuels, making them suitable for diverse applications.

Safety Features in High Flow Fuel Dispensers

Safety is paramount in the fuel dispensing industry. High flow fuel dispensers incorporate various safety features to minimize risks:

1. Automatic Shut-Off

This feature prevents overfilling and spillage, ensuring that fueling operations remain safe.

2. Leak Detection Systems

Modern dispensers are equipped with sensors to detect leaks, which can trigger alarms and shut down operations to mitigate hazards.

3. Emergency Stop Systems

An accessible emergency stop button allows operators to quickly halt fueling operations in case of an emergency.

4. Anti-Static Technology

To prevent static electricity buildup, high flow dispensers often include grounding mechanisms.

Maintenance and Reliability of High Flow Fuel Dispensers

Regular maintenance is crucial for high flow fuel dispensers to ensure their reliable operation. Key maintenance practices include:

1. Regular Inspections

Routine checks for wear and tear, especially on hoses and nozzles, help prevent failures.

2. Calibration of Flow Meters

To maintain accuracy, flow meters should be calibrated regularly as per manufacturer specifications.

3. Cleaning Filters

Keeping filters clean ensures that fuel quality remains high and prevents clogs that can hinder performance.

4. Software Updates

For dispensers equipped with electronic control systems, keeping software up to date is essential for optimal performance.

The Future of High Flow Fuel Dispensers

As technology continues to evolve, the future of high flow fuel dispensers looks promising. Innovations may include:

1. Smart Dispensers

Integrating IoT technology could allow dispensers to provide real-time data on fuel usage, maintenance needs, and more.

2. Enhanced Automation

Automation in fuel dispensing could further increase efficiency by minimizing the need for manual intervention.

3. Environmental Considerations

Future designs may focus on sustainability, with features aimed at reducing environmental impact and enhancing fuel efficiency.

FAQs

1. What is the typical flow rate of high flow fuel dispensers?

High flow fuel dispensers typically dispense fuel at rates exceeding 40 GPM.

2. Are high flow dispensers suitable for all types of fuel?

Yes, many high flow dispensers are designed to handle various fuels, including gasoline, diesel, and aviation fuel.

3. How often should high flow fuel dispensers be maintained?

Routine maintenance should be conducted at least once every six months, with more frequent checks depending on usage.

4. What safety features do high flow dispensers have?

High flow dispensers commonly include automatic shut-off systems, leak detection, and emergency stop buttons.

5. Can high flow fuel dispensers be automated?

Yes, many modern dispensers can be integrated with automation systems to enhance efficiency and reduce manual labor.

Conclusion

High flow fuel dispensers represent a significant advancement in fuel dispensing technology, delivering efficiency and reliability in fast-paced environments. Understanding the intricate technology and components behind these dispensers not only enhances knowledge but also aids in making informed decisions regarding fuel dispensing solutions. As the industry continues to evolve, staying updated on technological advancements will ensure businesses remain competitive in the ever-changing landscape of fuel retailing.