Exploring the Benefits of Submersible Fuel Pumps for Transportation Industries

Exploring the Benefits of Submersible Fuel Pumps for Transportation Industries

Table of Contents

1. Introduction to Submersible Fuel Pumps

2. What Are Submersible Fuel Pumps?

3. Advantages of Submersible Fuel Pumps in Transportation

3.1 Increased Efficiency in Fuel Delivery

3.2 Energy Savings and Cost Reduction

3.3 Safety and Reliability in Operations

3.4 Integr

Exploring the Benefits of Submersible Fuel Pumps for Transportation Industries

Table of Contents

- 1. Introduction to Submersible Fuel Pumps

- 2. What Are Submersible Fuel Pumps?

- 3. Advantages of Submersible Fuel Pumps in Transportation

- 3.1 Increased Efficiency in Fuel Delivery

- 3.2 Energy Savings and Cost Reduction

- 3.3 Safety and Reliability in Operations

- 3.4 Integration and Automation Benefits

- 3.5 Environmental Impact Considerations

- 4. Applications of Submersible Fuel Pumps in the Transportation Industry

- 4.1 Fuel Stations and Retail Outlets

- 4.2 Logistics and Freight Transport

- 4.3 Maritime Transportation

- 4.4 Aerospace and Aviation

- 5. Choosing the Right Submersible Fuel Pump

- 6. Frequently Asked Questions

- 7. Conclusion

1. Introduction to Submersible Fuel Pumps

The transportation sector relies heavily on efficient fuel management to keep operations running smoothly. As fuel consumption rises, the need for reliable and effective pumping solutions becomes increasingly important. **Submersible fuel pumps** have emerged as a game-changer in the industry, offering numerous advantages for fuel management systems. This article explores the benefits and applications of submersible fuel pumps specifically tailored for transportation industries.

2. What Are Submersible Fuel Pumps?

Submersible fuel pumps are devices designed to operate underwater, often submerged in fuel tanks or reservoirs. They function by pushing fuel to the surface, making them ideal for applications where above-ground pumps may be ineffective. These pumps are typically equipped with an electric motor that drives an impeller, ensuring a steady flow of fuel while maintaining high efficiency.

3. Advantages of Submersible Fuel Pumps in Transportation

Submersible fuel pumps offer various advantages that enhance their appeal within the transportation industry. Below are some of the key benefits:

3.1 Increased Efficiency in Fuel Delivery

One of the primary advantages of submersible fuel pumps is their efficiency in fuel delivery. Unlike traditional pumps that draw fuel, submersible pumps push it directly to the surface, which reduces the energy required to move fuel. This push mechanism ensures a consistent flow rate, allowing for faster refueling and improved turnaround times for vehicles.

3.2 Energy Savings and Cost Reduction

Submersible fuel pumps have the potential to significantly lower energy consumption. By operating submerged, they require less power compared to surface pumps. This energy efficiency translates into reduced operational costs. Additionally, the lifespan of these pumps is often longer, leading to fewer replacements and lower overall maintenance expenses.

3.3 Safety and Reliability in Operations

Safety is paramount in the transportation industry, especially when dealing with flammable fluids. Submersible fuel pumps minimize the risk of fuel spills and leaks as they are sealed and protected from external elements. Furthermore, their design ensures that they operate quietly and reduce the risk of vapor emissions, enhancing safety for operators and the environment.

3.4 Integration and Automation Benefits

Modern submersible fuel pumps can be integrated with advanced monitoring systems, allowing for automation in fuel management. This integration supports real-time data collection and analysis, enabling operators to optimize fuel usage and streamline their operations. Automation reduces the potential for human error and enhances overall operational efficiency.

3.5 Environmental Impact Considerations

The environmental impact is a crucial consideration in today’s fuel management practices. Submersible fuel pumps are designed with environmental sustainability in mind. Their efficiency and reliability reduce the likelihood of leaks, thereby minimizing contamination risks to local ecosystems. Additionally, energy-efficient pumps contribute to lower carbon footprints and promote eco-friendly practices in the transportation sector.

4. Applications of Submersible Fuel Pumps in the Transportation Industry

Submersible fuel pumps are versatile and can be utilized in various applications within the transportation industry. Below are some key areas where these pumps excel:

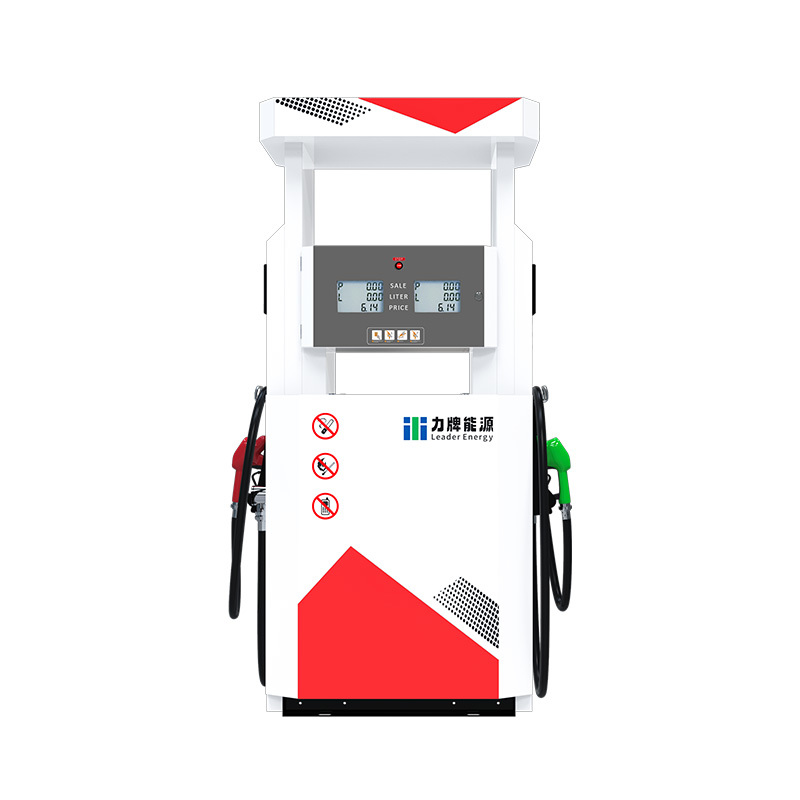

4.1 Fuel Stations and Retail Outlets

Fuel stations benefit greatly from submersible fuel pumps due to their reliability and efficiency in handling high volumes of fuel. They facilitate quick and efficient transactions, which is crucial for customer satisfaction. By integrating these pumps with automated systems, fuel stations can enhance their service offerings and streamline operations.

4.2 Logistics and Freight Transport

In logistics and freight transportation, fuel efficiency is critical for maintaining profitability. Submersible fuel pumps help ensure that fleet vehicles are refueled quickly and efficiently, minimizing downtime. This is especially important for long-haul trucking operations where time is a significant factor.

4.3 Maritime Transportation

The maritime industry also utilizes submersible fuel pumps for fuel management on ships and vessels. These pumps are essential in transferring fuel from storage tanks to engines, ensuring seamless operations while maintaining safety protocols. The submerged design is particularly advantageous in the marine environment, where other pump types may face challenges due to water exposure.

4.4 Aerospace and Aviation

In the realm of aerospace, submersible fuel pumps play a crucial role in the fueling process of aircraft. These pumps provide reliable fuel transfer, ensuring that aircraft are ready for takeoff without delays. Their efficiency contributes to overall operational effectiveness in the aviation sector.

5. Choosing the Right Submersible Fuel Pump

Selecting the right submersible fuel pump is vital for maximizing its benefits. Here are some considerations to keep in mind:

5.1 Key Considerations for Selection

When choosing a submersible fuel pump, consider factors such as flow rate, power requirements, material compatibility, and installation environment. Understanding the specific needs of your operation will guide you in selecting the most effective pump for your application.

5.2 Maintenance Tips for Longevity

To ensure your submersible fuel pump operates efficiently for an extended period, regular maintenance is crucial. Periodically inspect the pump for wear and tear, clean filters, and check for any potential leaks. Following the manufacturer’s guidelines for maintenance will help you avoid costly repairs and ensure optimal performance.

6. Frequently Asked Questions

1. What is the lifespan of a submersible fuel pump?

The lifespan of a submersible fuel pump can vary based on usage and maintenance, but with proper care, they can last anywhere from 5 to 15 years.

2. Are submersible fuel pumps energy-efficient?

Yes, submersible fuel pumps are generally more energy-efficient than traditional surface pumps, as they require less power to operate.

3. Can submersible fuel pumps be used in various types of fuel?

Submersible fuel pumps can be designed to handle different types of fuels, including gasoline, diesel, and biofuels, depending on the materials used in their construction.

4. How do submersible fuel pumps enhance safety?

Submersible fuel pumps minimize the risk of spills and leaks, operate quietly, and reduce vapor emissions, contributing to a safer working environment.

5. What maintenance is required for submersible fuel pumps?

Regular maintenance includes inspecting for wear, cleaning filters, checking seals, and ensuring the pump is free from debris and contaminants.

7. Conclusion

Submersible fuel pumps represent a significant advancement in fuel management for the transportation industry. Their numerous benefits—including increased efficiency, energy savings, reliability, and safety—make them essential for modern fuel systems. As the demand for efficient and sustainable fuel solutions continues to grow, the adoption of submersible fuel pumps will undeniably play a crucial role in shaping the future of transportation. Ensuring you choose the right pump and maintain it properly will help you reap the maximum benefits, allowing your operations to thrive in an increasingly competitive landscape.